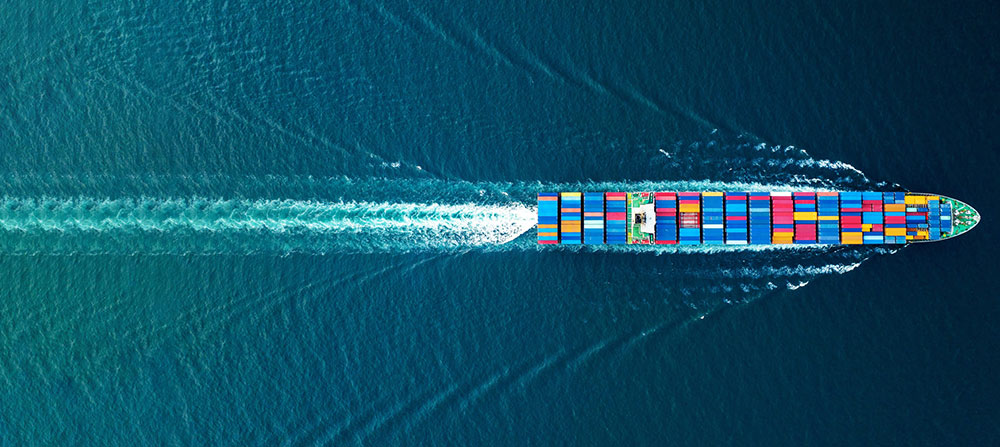

MARINE ADHESIVES

MAKO manufactures paste adhesive offsets to long lead time, high-priced items and can often provide superior lap shear properties and cost reduction. Use the form below to request a Technical Data Sheet for the right marine-grade adhesive. If your boat will use an infusion or wet layup process, our affiliate PTM&W can provide a low-viscosity liquid resin kit with superior properties to others in the market, while assuring they are MADE IN AMERICA with onshore supply chain for consistent resin batches and lower risk of supply chain frustration.

Applications

- Boat Building: Our formulations are used to construct durable hulls, decks, and structural components, extending the life of marine vessels.

- Subsea Equipment: MAKO products contribute to the development of reliable subsea equipment, ensuring longevity and safety.

- Radomes, Marine & Navy: MAKO low-dielectric prepregs are used in the construction of ship-borne radomes for the highest performance. Epoxy or cyanate ester resin formulas coupled with high performance glass or quartz fibers are used depending on the specifications of your design. Contact MAKO below to work with our technical response team.

- Autonomous sea vessels: MAKO prepregs and adhesives are used in the growing unmanned sector, including marine vessels at surface and under sea. Contact MAKO to see how we can assist your engineering teams in the design phase to best utilize our composite materials.

- Repair and Maintenance: MAKO adhesive offsets to DP460, DP420, DP100, and DP125 are used in repair and maintenance operations for marine vessels and structures. They provide strong adhesion, durability, and compatibility with various repair materials, ensuring effective and long-lasting repairs.

Why This Industry Needs Our Formulations

The marine industry relies on MAKO prepregs & adhesives for their unmatched properties that address critical challenges specific to marine environments. These materials offer exceptional corrosion resistance, crucial for structures exposed to saltwater, thereby extending the lifespan of marine vessels and infrastructure while reducing maintenance costs. Their superior water and moisture resistance prevent degradation and maintain structural integrity. Versatile in manufacturing, MAKO out-of-autoclave prepregs support efficient production methods for large parts, and customizable formulations tailored to specific marine needs.

CUSTOM FORMULATING

At MAKO Advanced Materials, we offer specialized custom epoxy formulations precisely engineered to meet your unique needs. Collaborate with our experts to exceed your expectations and shape materials according to your vision.

PRODUCT DEVELOPMENT

MAKO Advanced Materials offers tailored solutions for your unique needs, including custom product development, white-labeling, and expert kitting & packaging services. We provide a contact form and phone number, and our team can follow up to assist you further.

Comprehensive Services

At MAKO Advanced Materials, we provide a comprehensive suite of specialized services. From custom resin development to white-label prepregs & adhesives, we cater to your diverse project needs, ensuring excellence and efficiency throughout.